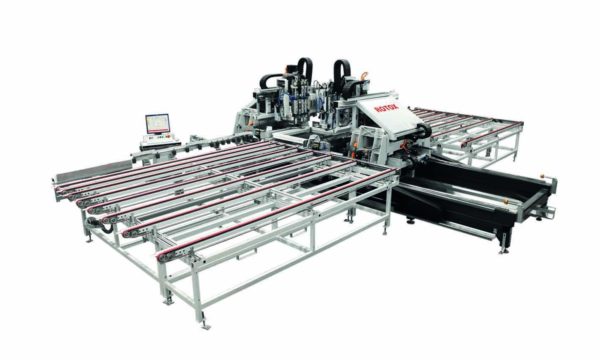

EKA 577

Advantages

- Modular design of the whole machine

- Variable tooling with up to 16 tool places +

contour milling disk / processing head - Fully automatic cleaning of the corner and transom

welding connections on uPVC window frames and sashes

as well as on sill frames, mullion combinations and offset

weldes profiles - The profile support side can be chosen before specification

- High processing quality owing to spring-mounted knifing

units compensating profile tolerances in the inner corner area - Easy program editing for additional profile contours by copy

programming and modification - SPS and interpolating CNC control with 12 axes

- Linear transport of the frames over belts

- Transom processing in clamping by espacial turing tool

- Pneumatic clamping system

- PC for visualisation

Technical data

Power (kW)

17

Voltage (V)

400

Operating pressure (bar)

7

Air consumption (l/m)

approx. 560

Workable profile width (mm)

50 - 130

Workable profile height (mm)

50 - 180

Min. frame size (mm)

min. 310 x 170 (inner measure)

Machine dimension L x D x H (mm)

9.400 x 7.200 x 2.100

Weight (kg)

approx. 7.600

Any questions? Contact your personal contact person here.

Click here.