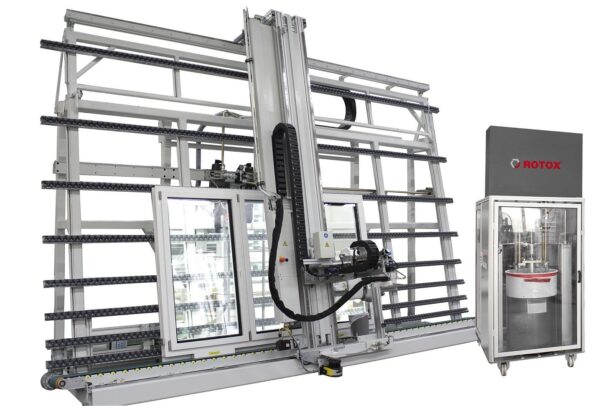

GKA 241

Advantages

- PC control with colour display

- Servo controlled mixing unit incl. gear pump

for dynamic regulation of the applied quantity - Variable mixing of the two component adhesives

in a ratio 100 : 50 to 100 : 2 - Flowing rate control for permanent measuring and

controlling of the desired mixing ratio and reducing

of set-up and check time - Monitoring of the pressure for guarantee of

process reliability - Data locking system for a permanent quality

reliability and a CE-conform documentation for

example: registered operator, date, time barrel or

charge number, mixing ration, applied quantity,

application time - Separate monitoring of the liquit level for dispose

of the next barrels - Tube packets (2,5 m) with mixing unit and

pivot arm - CE-conform casing

- Easy integration into automation concepts

- Optional extras:

- Mobile barrel support

- Special adhesive nozzle for rebate bonding

for the window construction - Manual mobile barcode scanner

- Several handling systems

Technical data

Output of adhesive quantity (kg/per min.*)

max. 1

Power (kW)

13

Voltage (V)

400

Operating pressure (bar)

6

Air consumption (l/min)

600

Material pressure (bar)

200

Length of pivot arm (mm)

2.500

Material tube (mm)

2.500

Barrel dimensions (Liter)

200 (A) / 20 (B)

Mixing ratio

100 : 50 - 100 : 2

Adhesive range (mm)

2.700 x 2.300 / 3.700 x 2.300 / 3.700 x 3.000

Any questions? Contact your personal contact person here.

Click here.