ROTOX-

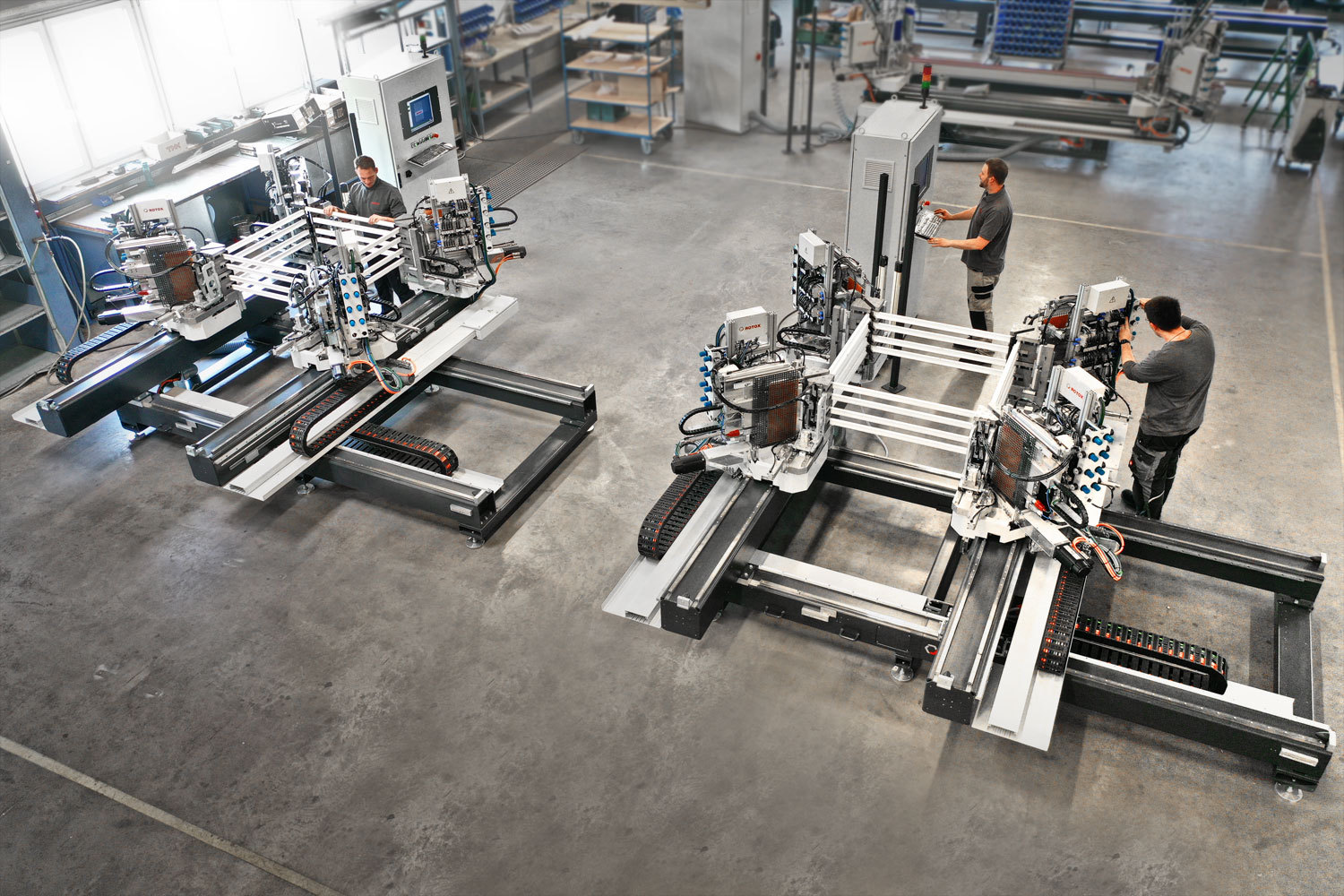

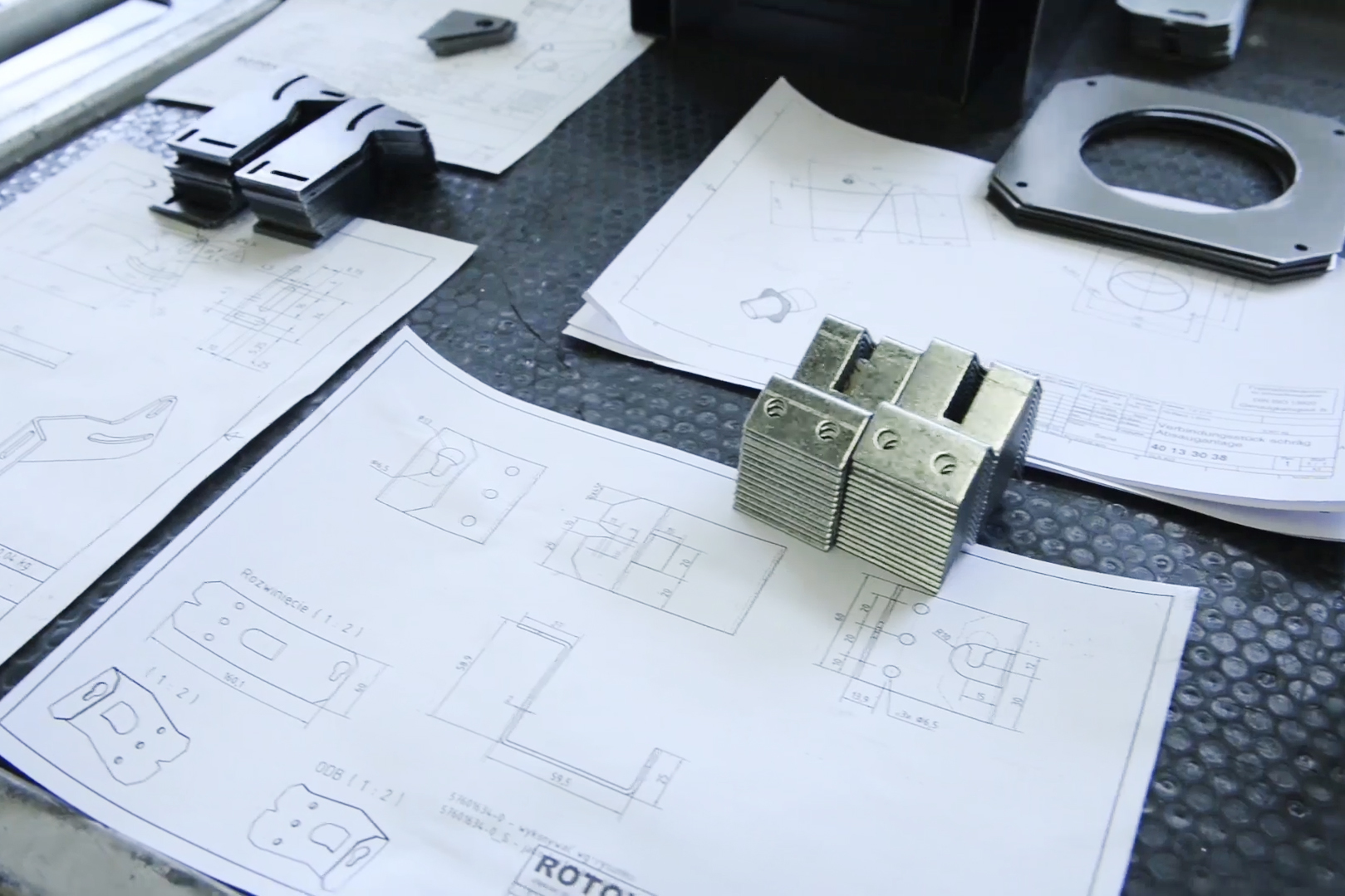

Machines and plants for window construction

The company

Our Company has History. Since 1970 our customers have valued our machines and systems for their productivity and quality. With Locations in Germany, Europe and the USA and worldwide partners, we are magor provider in the window machine sector for PVC and aluminium. We are constantly strengthening our team and training our specialists ourselves, making ROTOX the ideal partner for your Career.

News from ROTOX